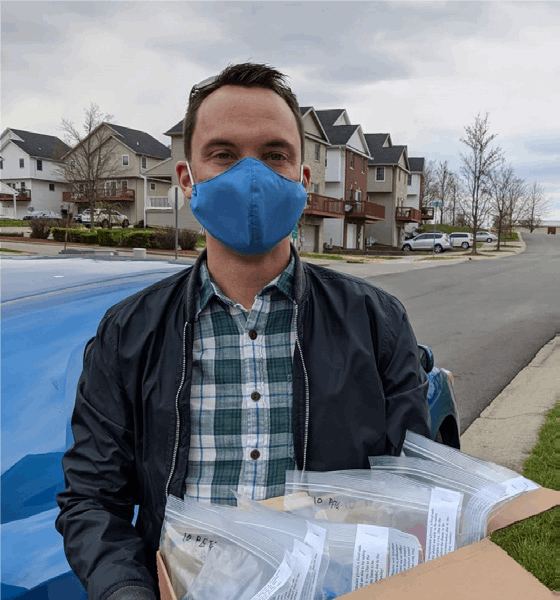

Chicago-based First Officer Andrew Loder found himself with a little extra time on his hands recently. With the nationwide shortage of personal protective equipment (PPE), Andrew is volunteering his time and resources to a worldwide organization called "Masks for Docs," whose sole purpose is to get PPE into the hands of healthcare workers as fast as possible.

Using his 3D printer, Andrew is making National Institute of Health approved face shields that get cleaned, packaged, and delivered to doctors, nurses, and other healthcare workers. The Swedish shield design was recently approved for use in the United States by the NIH and was picked up by volunteer organizations around the world.

It has taken several hours and dozens of attempts with different settings to perfect Andrew's printing. "Now, it takes my machine about 56 minutes to print two of the frames for the face shield, and an additional three minutes of cooling, reheating, and setup time in between prints," he said. "If I am home all day, I can make 28-30 frames." The print happens autonomously once he starts the machine, so he uses that time to prepare the rest of the face shields for delivery. The face shields are designed to be easily disassembled and cleaned.

Andrew's dad, sister, and brother-in-law are all doctors, and another sister is a nurse. "The idea that I could do anything to effect even a small change in this pandemic is a powerful motivator," he said.

Andrew became interested in 3D printing in middle school, but he officially got involved about 15 months ago when he bought his printer. "My 7th-grade science teacher had a team of mechanical engineering students come and visit us with parts to a machine they had designed and printed using one of the earliest commercially-available printers," said Andrew. "The idea of being able to rapidly manufacture virtually anything I could imagine totally captivated my imagination, and I decided then that I would eventually buy one for my use," he said.

Andrew’s 3D printing hobby, now volunteer effort, combines computer-aided design (CAD), light computer programming, and creative problem-solving. 3D printing has many commercial applications, including the fuel nozzles in the A320neo’s LEAP-1A engine.

"I'm pretty passionate about this," Andrew said. Andrew can now make and deliver about 18-24 per day and has delivered more than 190 face shields with no plans to stop. There are several similar organizations to "Masks for Docs," but this one is 100% volunteer-driven and organized at a local level via Slack.

To learn more about “Masks for Docs” click here.